PrinTimber Outreach Activity Teaches High School Students About Molecular Deformation and Additive Manufacturing

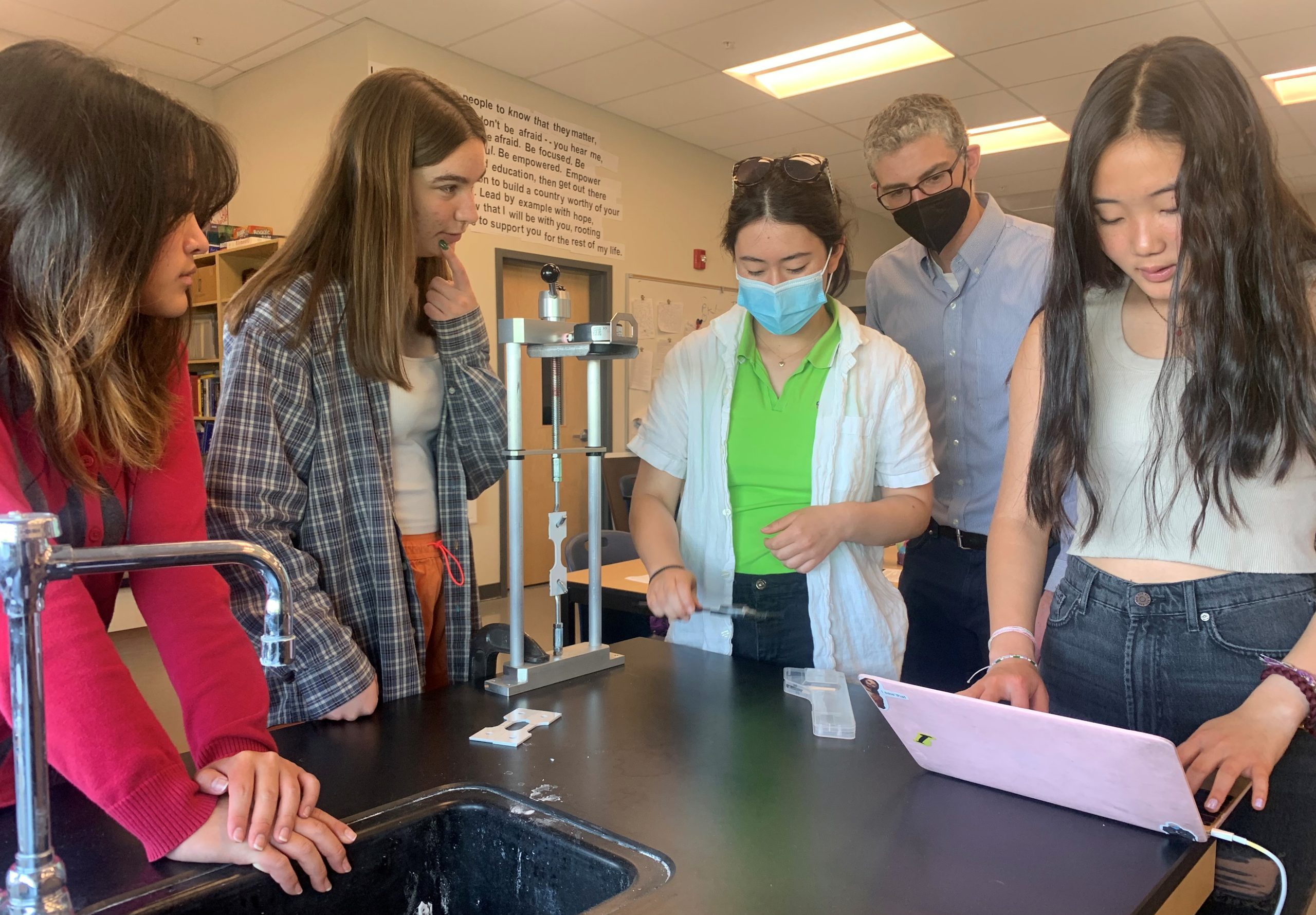

In May, Pullman High School AP Chemistry students learned about the molecular deformation of polymers through a hands-on class taught by Mechanical Engineering Assistant Professor and PrinTimber Principal Investigator Michael Maughan.

The lesson taught the students what happens to polymers when they are stretched on a molecular level. This basic concept is a fundamental building block of science. It is utilized in the additive manufacturing – also known as 3D printing – process of the PrinTimber project, a University of Idaho-led grant funded by the National Science Foundation (NSF).

The students were introduced to PrinTimber’s additive manufacturing project, its goals, and its impact on the environment. The project uses 3D printing technology to transform timber waste materials into housing components, which makes houses more affordable and sustainable while tackling climate change. The lesson was part of the recent workforce development activities associated with the project. These activities, such as network mentoring and helping early career faculty become productive researchers, are part of an effort to build capacity in underrepresented jurisdictions and get students with advanced degrees into the industry. For these high schoolers, the lesson was taught to foster interest in science and teach a concept that is not part of a typical high school curriculum.

Students completed two Process Oriented Guided Inquiry Learning (POGIL) worksheets provided by Maughan and Pullman High School chemistry teacher Johanna Brown: one on polymer molecular deformation, and the other on tensile testing and generating stress versus strain curves. After the assignments, Maughan gave an informational presentation on state-of-the-art activities at the University of Idaho along with a more thorough discussion on polymer microstructure.

Students worked in groups to conduct a tensile test using hand-operated test frames on polypropylene specimens, which are known for being flexible and lightweight. The groups were then asked to share their perception about what happened in the experiments at the molecular level. Maughan, Brown, and the students compared their ideas with established experimental findings shown by refined tensile tests and electron microscopy studies.

Each of the 38 student participants left with a U of I Vandal swag bag from the College of Engineering and new knowledge on the molecular deformation of polymers.